Electroless nickel plating to improve solder wettability

(automotive parts)

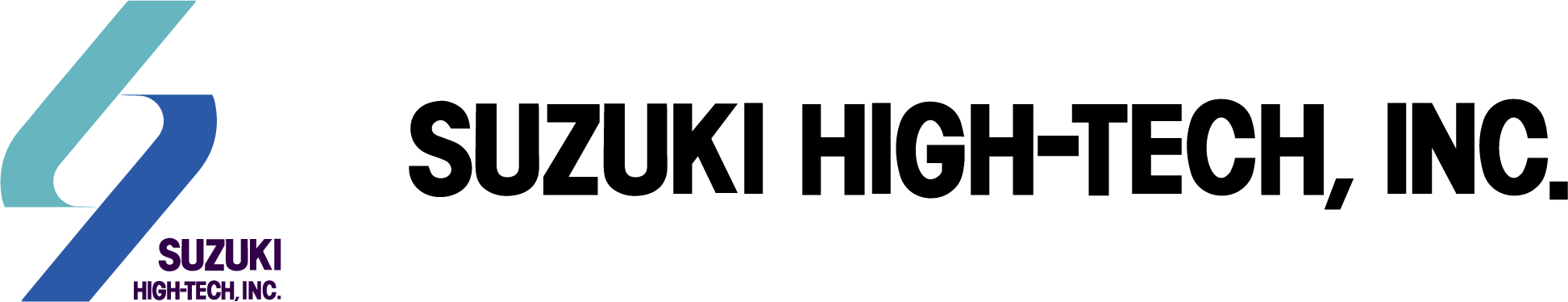

Our electroless nickel plating can be conducted according to product specifications.

High phosphorus, medium phosphorus, and low phosphorus can be selected, and mass production can be handled by automated machines.

We also support production for cooling plates and battery parts for HEV, PHEV, BEV vehicles, etc.

We satisfy strict in-vehicle quality requirements.

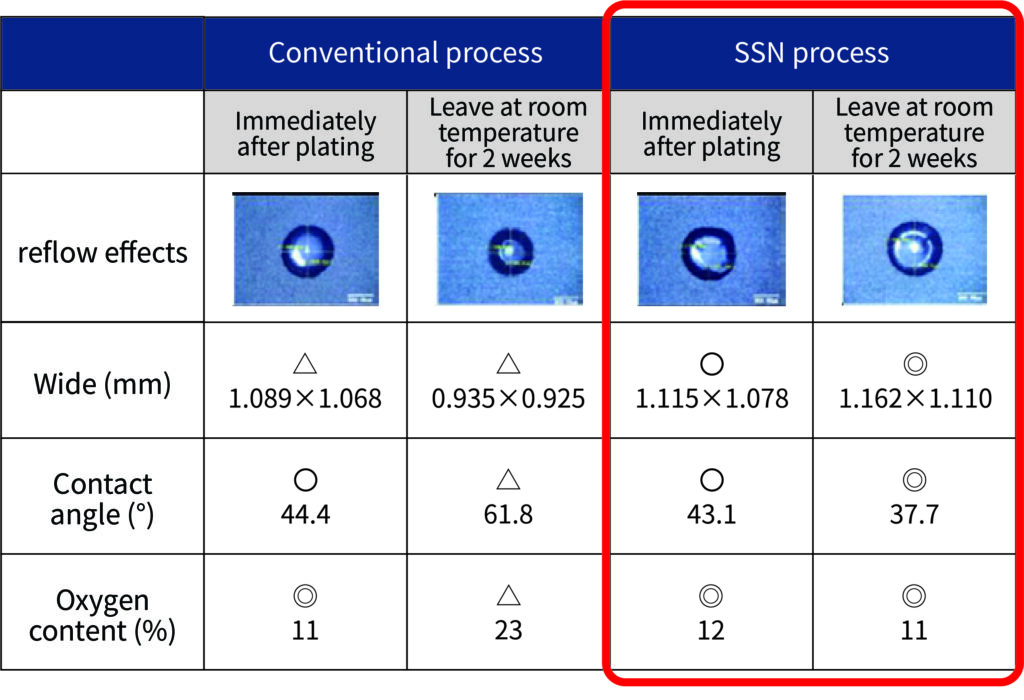

Electroless nickel plating with high phosphorus has a trade-off correlation between corrosion resistance and solder wettability, but our original plating technology (SSN process) improves the low solder wettability of the high phosphorus type nickel plating. The SSN process strengthen the solder joint performance while maintaining high corrosion resistance. We provide stable high-quality processing that meets strict in-vehicle quality requirements.

Plating technology using SSN process also compatible with low phosphorus type nickel plating.

It can be selected between high to low phosphorus according to the specifications of customer's products.

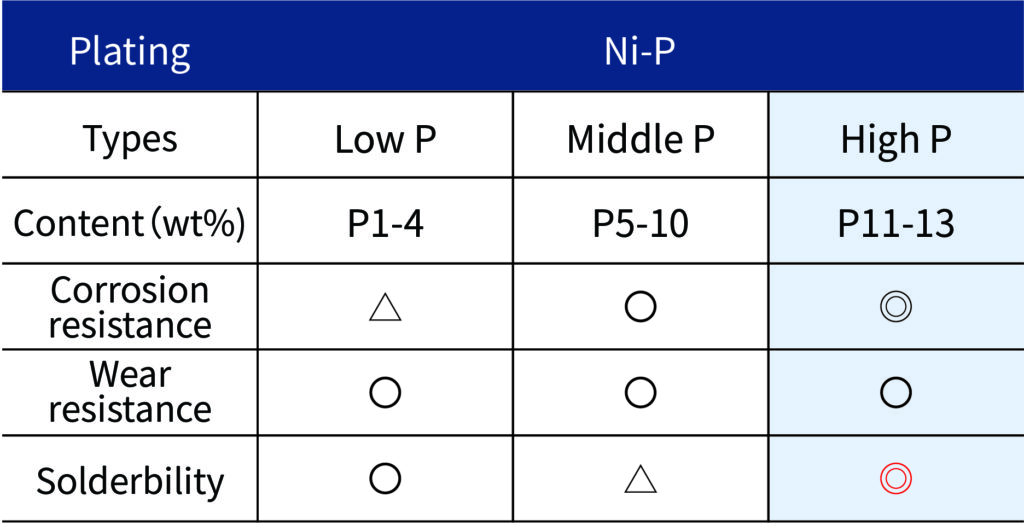

SSN process improves solder wettability of high phosphorus type and enables high-strength bonding performance.

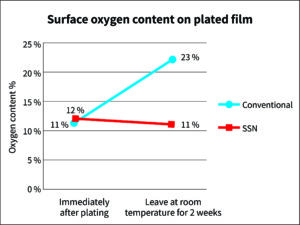

The results of solder wetting test using reflow and surface oxygen content measurement showed that

even after 2 weeks, the solder still wets and spreads well on the SSN process plating film.

The film prevents the formation of an oxide film and has good solder bonding.

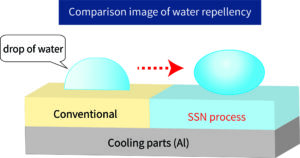

SSN process improves corrosion resistance.

The film of the SSN process has excellent water repellency and prevents moisture penetration,

and since it prevents the formation of an oxide film on the surface of the material, it can be expected to improve corrosion resistance.

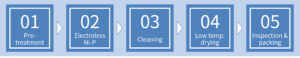

Process flow in SSN process

Plating with the SSN process can meet various needs using the latest automatic plating equipment.

Highly efficient production system with centralized management system automates process flow and

stable mass production can be achieved by 24-hour operation.

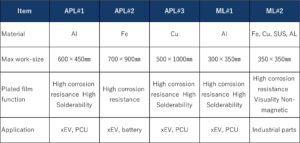

Automated plating line #1 (Al)

Automated plating line #2 (Fe)

Automated plating line #3 (Cu)

Manual plating line #1 (Al)

Manual plating line #2 (Fe, Cu, SUS, Al)