CFRP Plating Process (Material: Carbon + Thermosetting Resin)

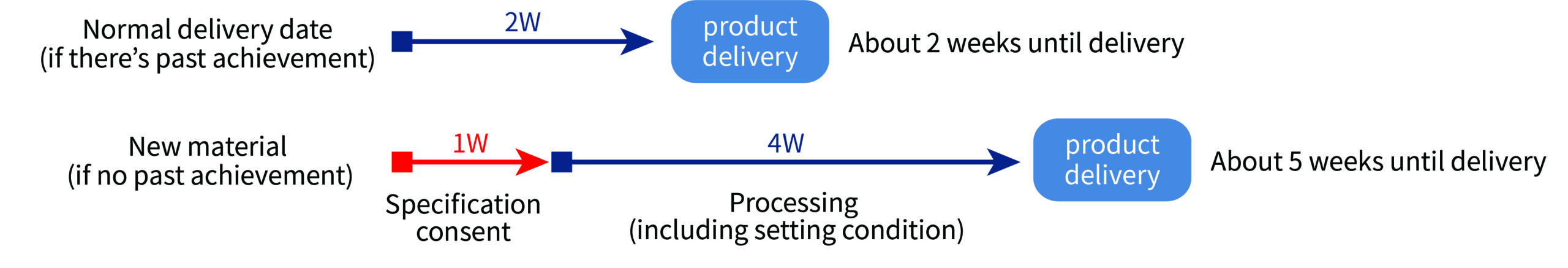

Our CFRP plating technology can be applied to any type of CFRP base resin (thermosetting or thermoplastic) and any molding method (rolling, cutting, heat treatment, 3D printing, etc.). Our original surface treatment technology can be applied to all types of CFRP.

Our advanced process development capabilities and state-of-the-art facilities, combined with 100 years of technological know-how, enable us to provide high quality plating with high adhesion for difficult-to- plate CFRP.

Solving the Problems of CFRP, an Ideal Lightweight Material

In addition to features such as high strength and high rigidity, CFRP also has features such as low thermal expansion, self-lubricity, and X-ray permeability.

By taking advantage of these features, they are widely used in various applications and industries.

However, CFRP has some problems in terms of weather resistance and abrasion resistance, such as ultraviolet rays, humidity (rain and fog), sea salt, and friction. Through our CFRP plating process, we are able to add metallic properties to CFRP to solve these issues.

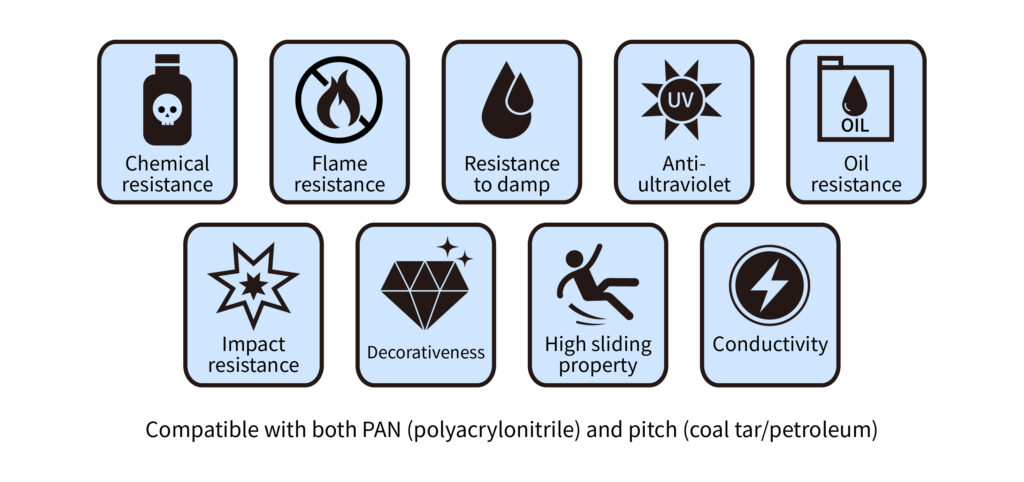

Functionality that can be expected to improve

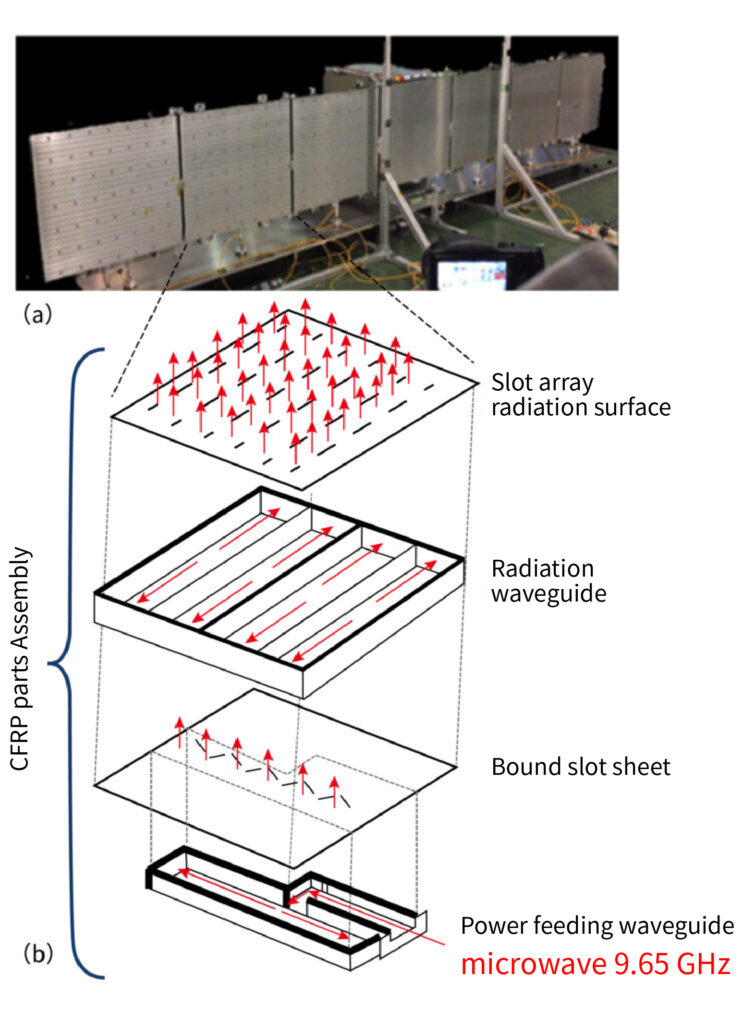

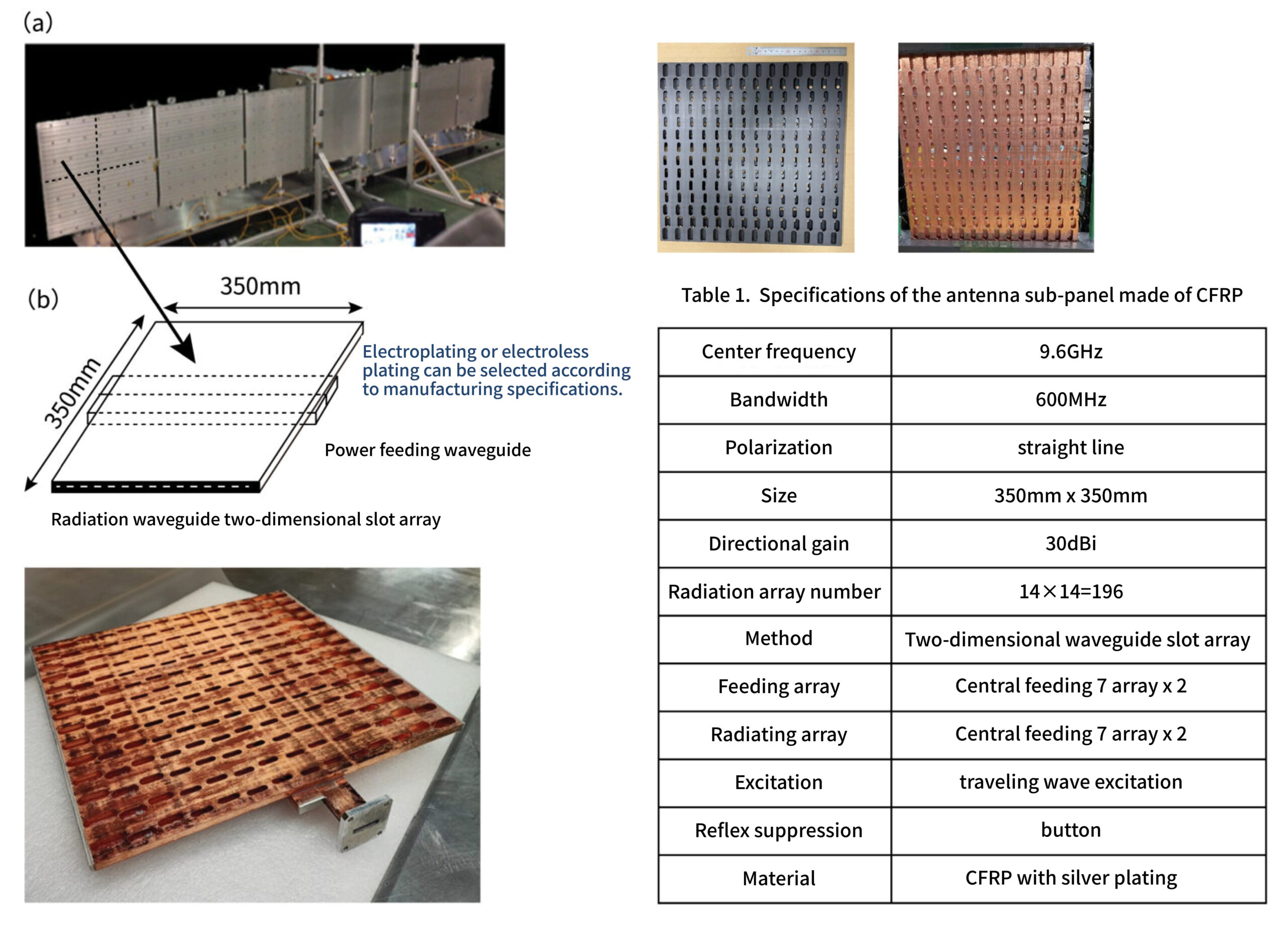

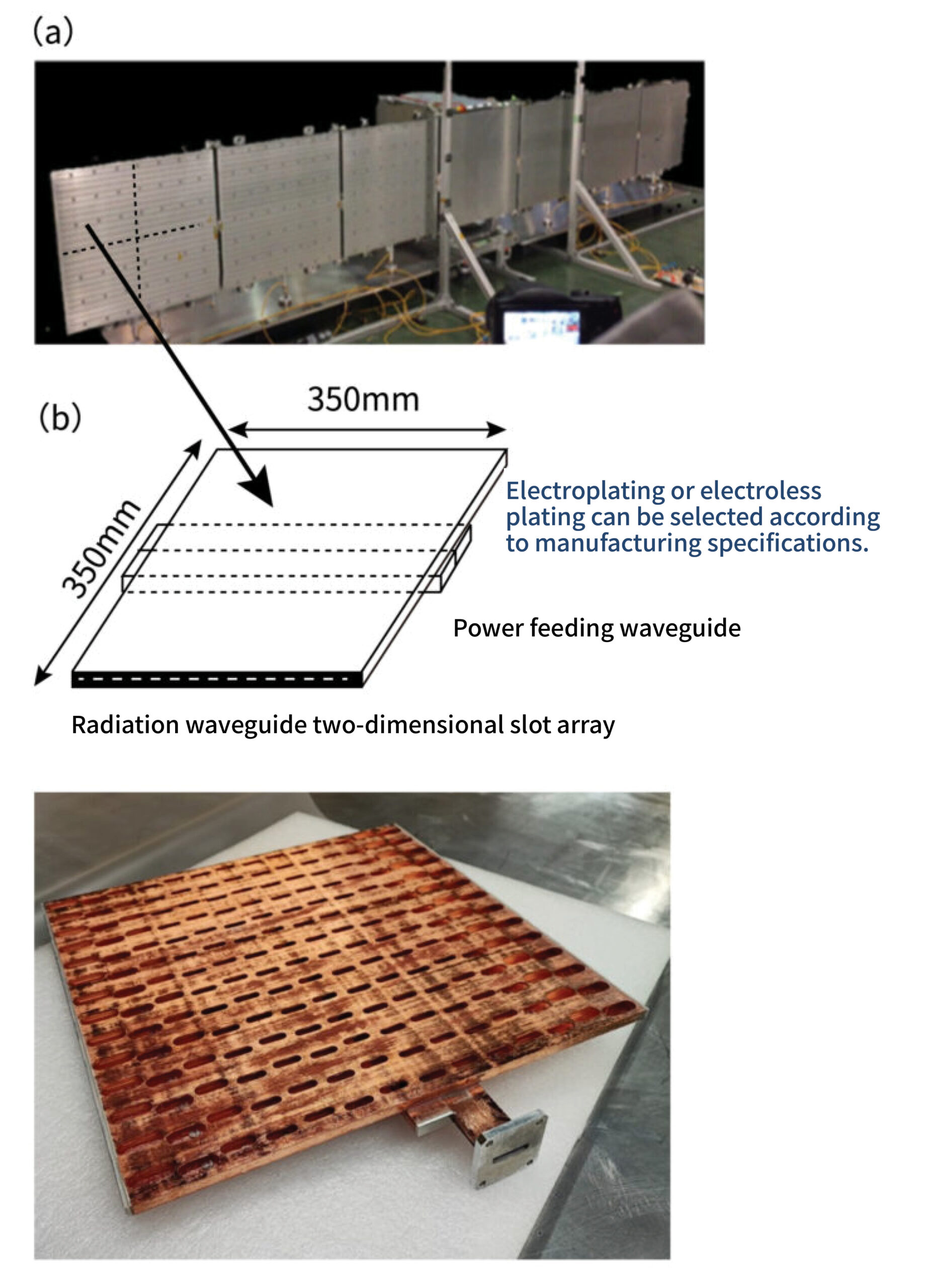

①Development Example of Deployable Panel Slot Array Antenna Made of CFRP

A deployable slot array antenna to be mounted on a 100 kg-class synthetic aperture radar satellite must be lightweight and have a stable shape that does not deform in the thermal environment of the satellite's orbit. For this reason, antennas with the power-feeding and radiating circuits made of CFRP have been developed, because CFRP has an extremely low coefficient of thermal expansion.

Our plating technology is used to improve the conductivity of these CFRP’s antennas.

(a)SAR antenna (4.9mx0.7m) deployed from a 100kg class small satellite

(b)Structure of CFRP antenna panel under development

Source : IEICE Technical Report-Professor Emeritus JAXA, Dr. Hirofumi Saito (Waseda Univ.), Dr. Ishimura (Waseda Univ.), and others.

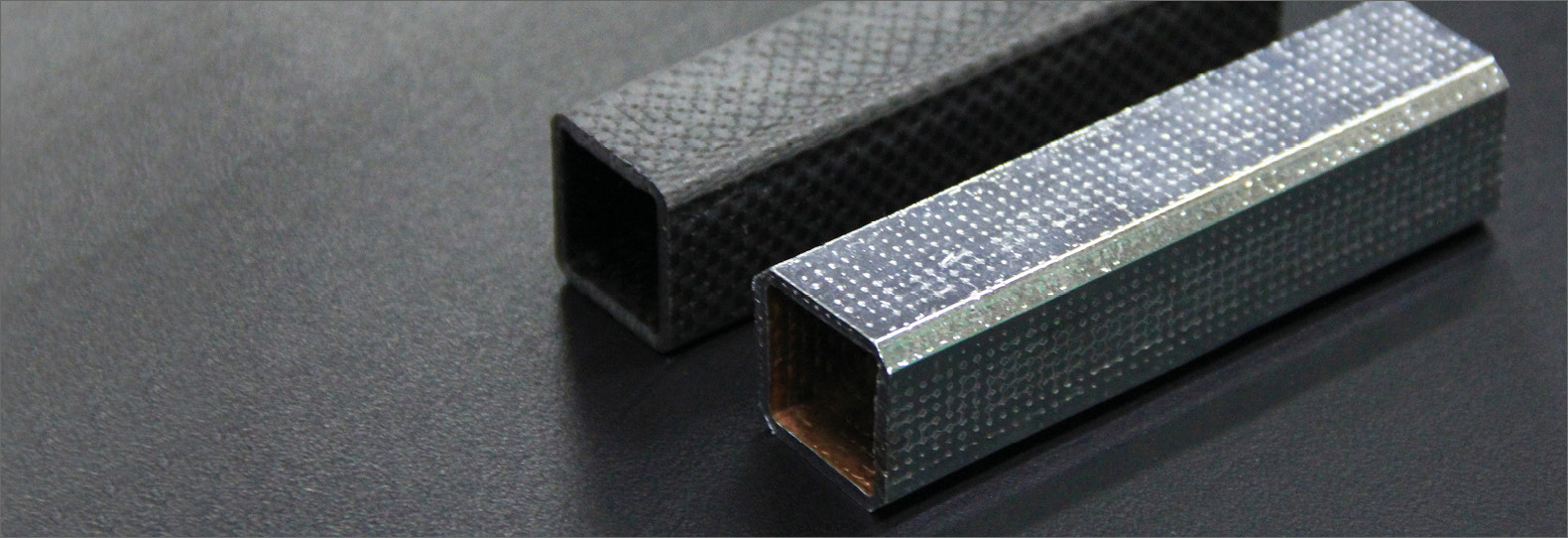

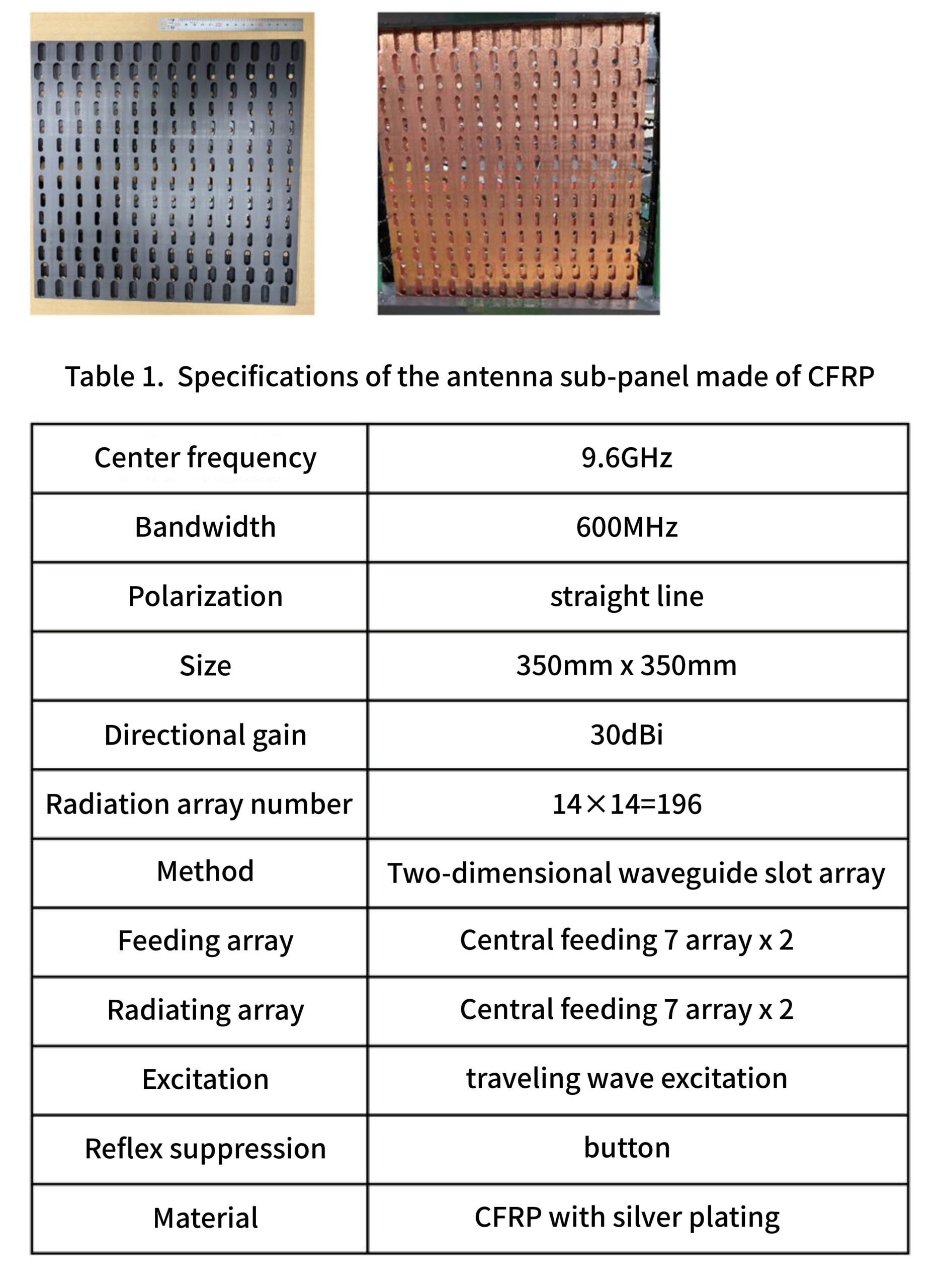

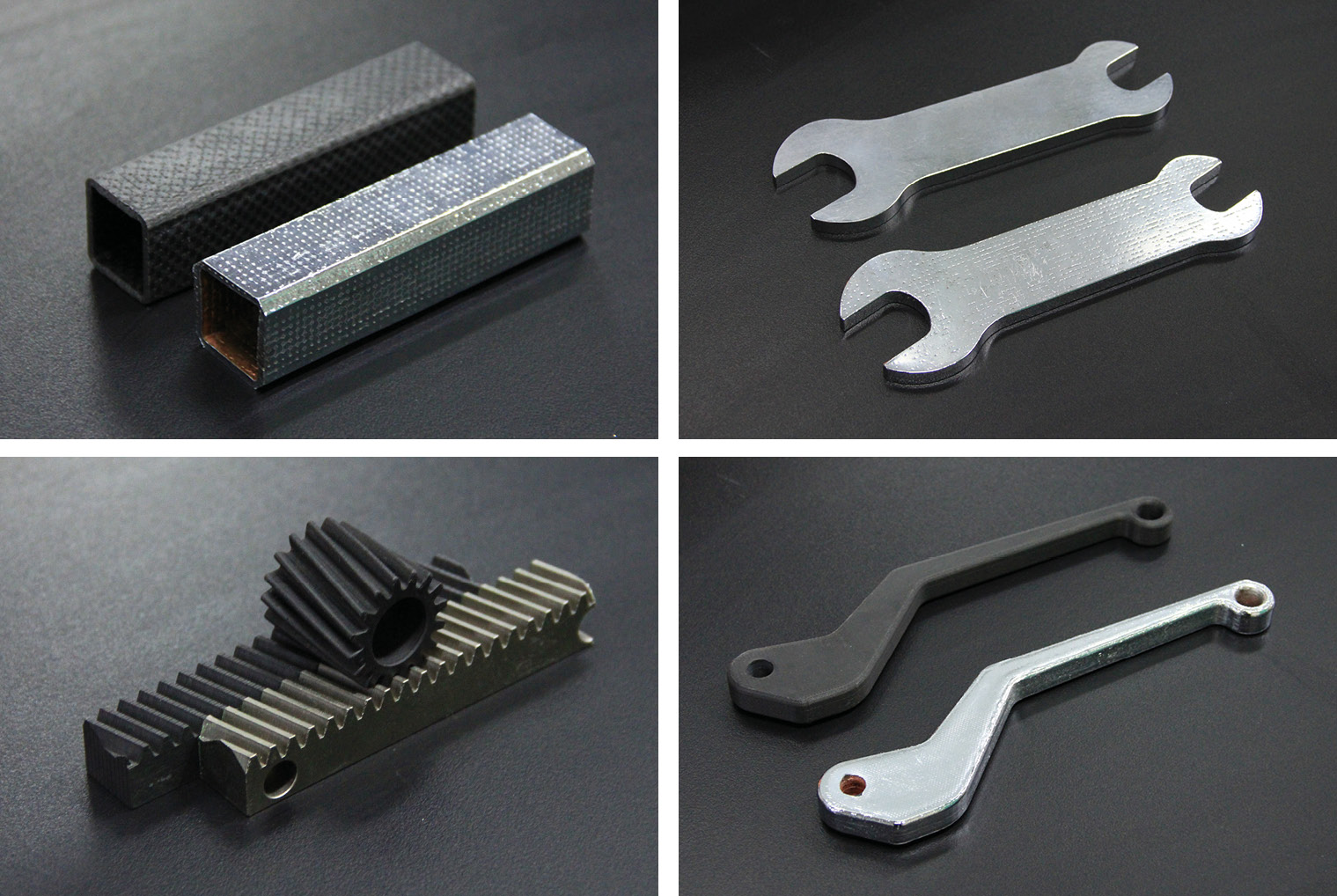

②Examples of Plating Treatment for CFRP Molded Products

We provide a plating treatment with high adhesion and high sliding surface properties for CFRP molded products, and we accept at least one workpiece order.

We also can provide a proposed plan from development prototypes to mass production of tens of thousand units per month, as well as process simplification to reduce manufacturing costs and improve productivity.

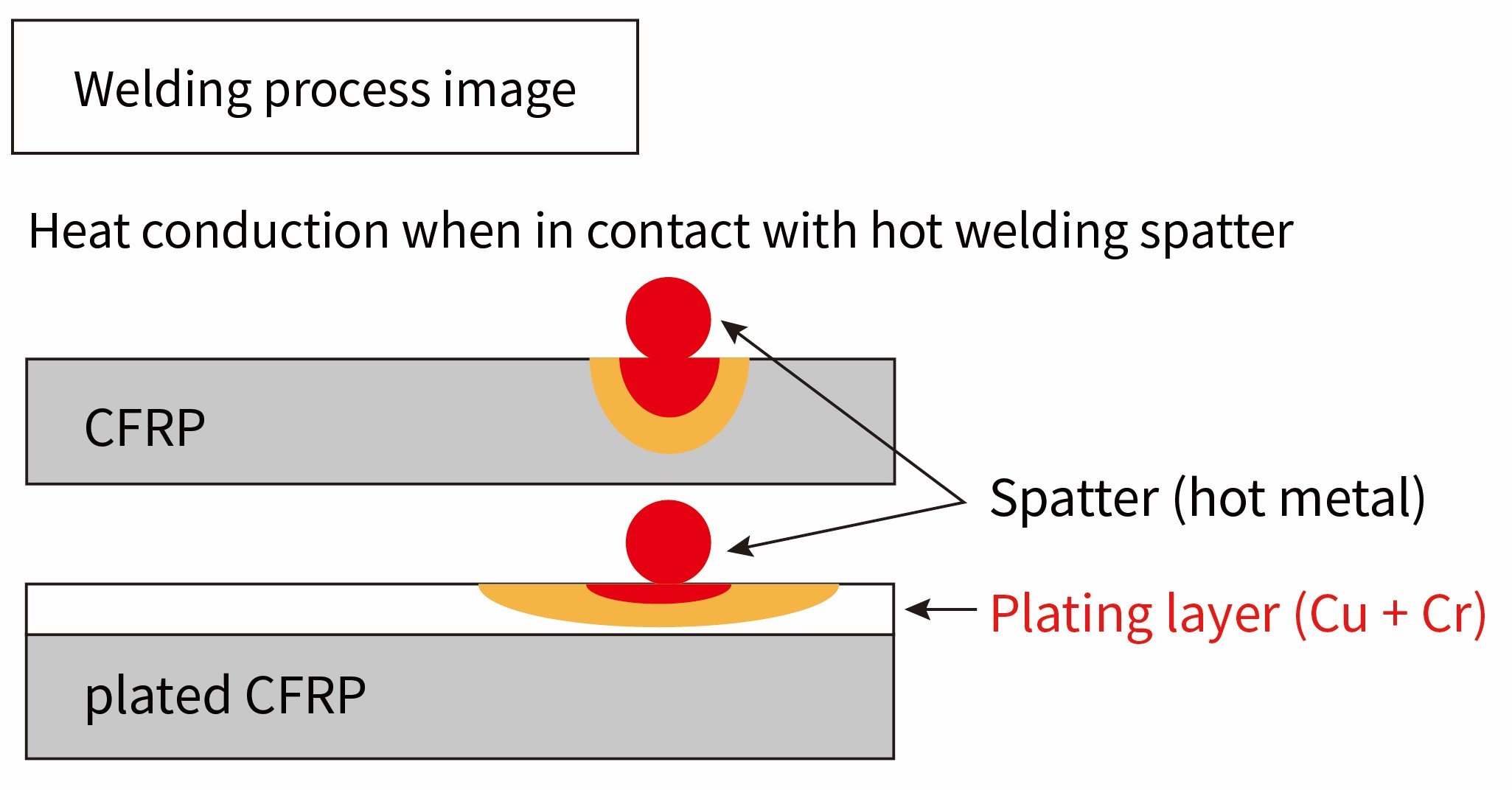

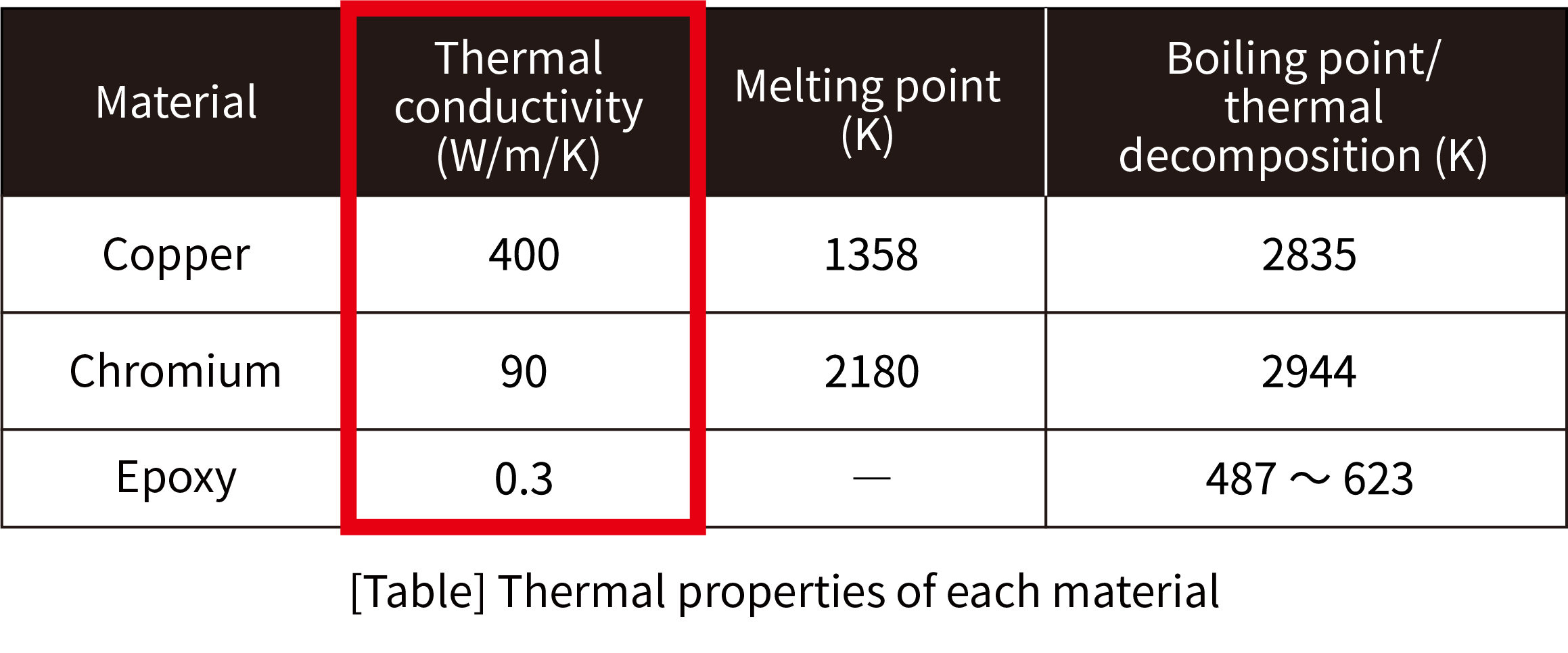

③Proposal Example: Addition of Flame-Retardant Property to CFRP Through Our Original SMC Process (High Slidability Plating)

Thermal conductivity of plated metals (copper or chromium) is 300-1300 times higher than that of epoxy resin which mainly used for CFRP base materials.

Since the plating film spreads heat quickly and prevent local heat accumulation, it has the effect of suppressing combustion of CFRP molded products

(flammability testing UL-94 V-0 compliant).

UL-94 V-0 compliant certified by Chemicals Evaluation and Research Institute (General incorporated foundation).

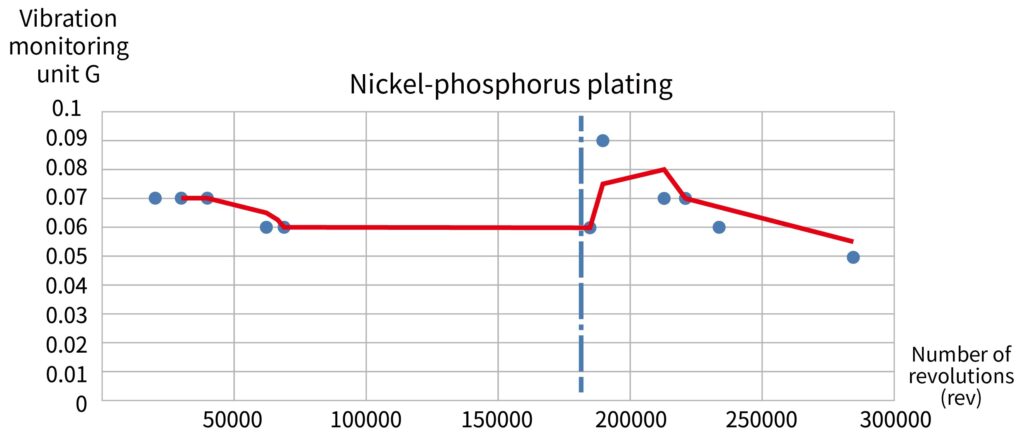

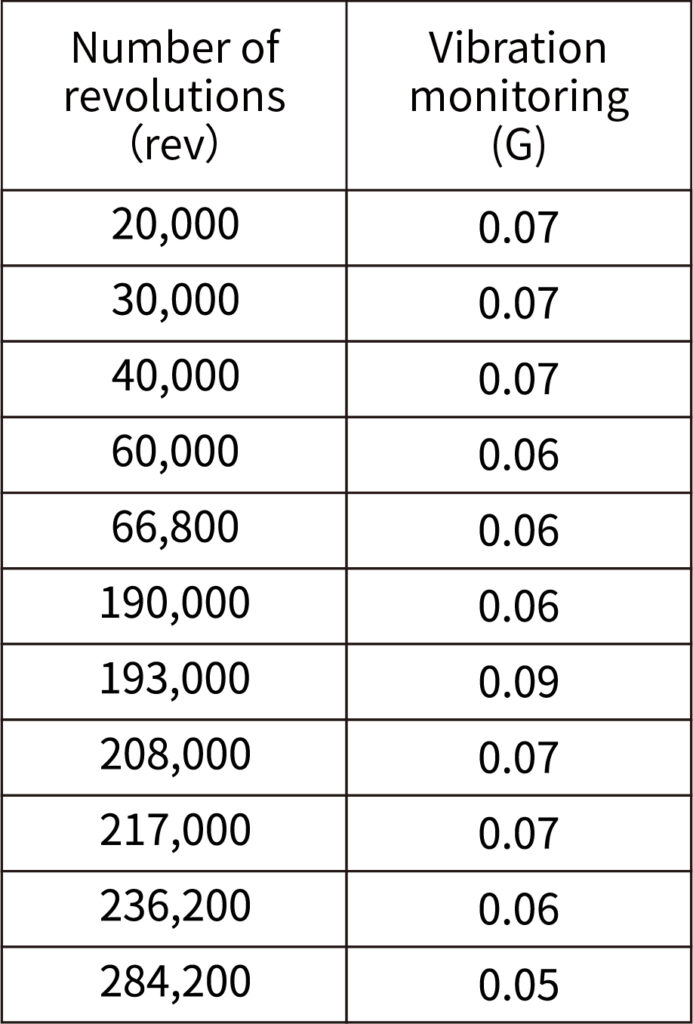

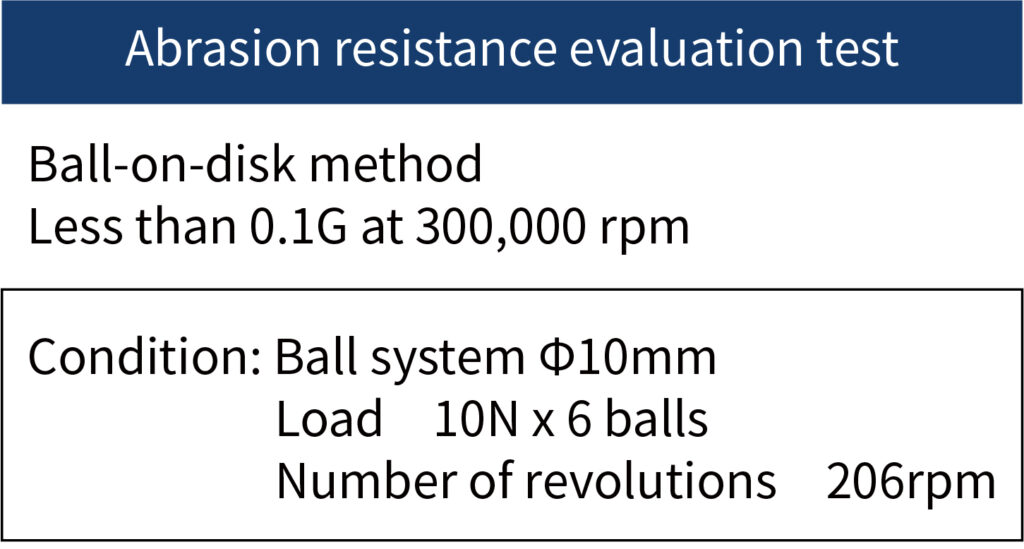

④Proposal Example: Functionality Improvement by Electroless Nickel Composite Plating

We have developed a unique process that relieves internal stress that causes cracking and peeling of plated metal.

The intermediate layer is thickened to achieve strong adhesion without peeling from the mold or deformation of the base material. At the same time, slidability and wear resistance are improved.